A gear train is a combination of gears used to transmit motion from one shaft to another. The followings are main type of gear trains:

- Simple Gear Train

- Compound Gear Train

- Reverted Gear Train

- Planetary or Epicyclic Gear Train

Speed Ratio and Train Value:

It is the ratio of the speed of driving gear to that of the driven gear. The reverse of the speed ratio is known as train value.

\[\boxed{Train\quad value = \frac{1}{Speed \quad ratio}}\]

1. Simple Gear Train

All the gear axes remain fixed relative to the frame and each gear on the separate shaft.

|

| Simple Gear Train |

By gear rules: $ \frac{N_2}{N_1} = \frac{T_1}{T_2}$, $ \frac{N_3}{N_2} = \frac{T_2}{T_3}$, $ \frac{N_4}{N_3} = \frac{T_3}{T_4}$, $ \frac{N_5}{N_4} = \frac{T_4}{T_5}$

\[Train\quad value = \frac{N_5}{N_1} = \frac{N_5}{N_4 } * \frac{N_4}{N_3 }*\frac{N_3}{N_2 }*\frac{N_2}{N_1 } = \frac{T_4}{T_5 }*\frac{T_3}{T_4 }* \frac{T_2}{T_3 } * \frac{T_1}{T_2 }\]

\[Train\quad value = \frac{T_1}{T_5} = \frac{number \quad of \quad teeth \quad on \quad driving \quad gear}{number \quad of \quad teeth \quad on \quad driven \quad gear}\]

Note:

- Two external gears of a pair always moves in opposite direction. For example gear 3 is anti CW then gear 4 is CW in direction.

- All odd number gear(1,3,5) moves in one direction and all even number gear(2,4) moves in the opposite direction.

- The intermediate gears have no effect on the speed ratio or train value therefore they are known as idlers.

2. Compound Gear Train

When a series of gears are connected in such a way that two or more gears rotate about an axis with the same angular velocity.

\[Train\quad value = \frac{N_4}{N_1} = \frac{T_1*T_3}{T_2*T_4} = \frac{product \quad of \quad number \quad of \quad teeth \quad on \quad driving \quad gear}{product \quad of \quad number \quad of \quad teeth \quad on \quad driven \quad gear}\]

3. Reverted Gear Train

It is a compound gear trian where input gear axis and output gear axis coincides.

|

| Reverted Gear Train |

\[Train\quad value = \frac{N_4}{N_1} = \frac{T_1*T_3}{T_2*T_4} = \frac{product \quad of \quad number \quad of \quad teeth \quad on \quad driving \quad gear}{product \quad of \quad number \quad of \quad teeth \quad on \quad driven \quad gear}\]

also,

\[r_1 + r_2 = r_3 + r_4\]

\[m_{12}[T_1 + T_2] = m_{34}[T_3 + T_4]\]

m is the module of the gear

4. Planetary or Epicyclic Gear Train

|

| Epicyclic Gear Train |

- Epicyclic gear train is the one in which the axis of some gears have relative motion.

- Large speed reductions are possible with epicyclic gears.

- Important application of epycyclic gears are in transmission, computing devices.

Relative Velocity Method

$N_{pa}$ : Angular vel. of P relative to arm a = Np - Na

$N_{sa}$ : Angular vel. of S relative to arm a = Ns - Na

\[\frac{N_{pa}}{N_{sa}} = -\frac{T_s}{T_p}\]

\[\boxed{\frac{N_p - N_a}{N_s - N_a} = -\frac{T_s}{T_p}}\]

Tabulation Method

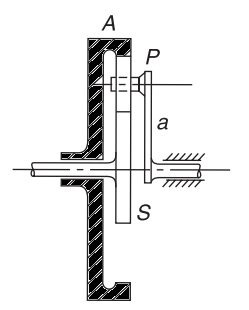

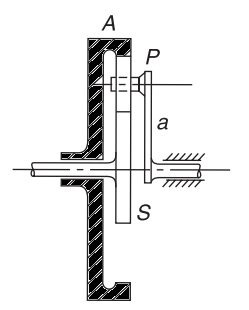

5. Sun and Planet

When an annular wheel is added to the epicyclic gear train, the combination is referred as Sun and Planet gear train.

|

| Sun and Planet Gear Train |

In general, S, A and a are free to rotate independently of each other. Table can be prepared:

References:

***

If you have any query, ask in comments.